DOE Fabrication: 3D Shaping

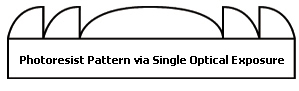

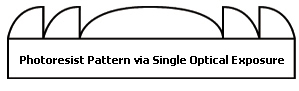

High Energy Beam Sesitive (HEBS) glass offers the advantages of a one step fabrication of a true gray level mask. The exposure of this gray level mask is done in a standard e-beam writing tool. This allows the use of all the existing software previously written to support mask making and direct write on resist approaches for the fabrication of diffractive optical elements (DOEs). The so generated gray level mask can be used in an optical exposure tool (eg, a G-line stepper, or a contact printer) to mass fabricate resist profiles.

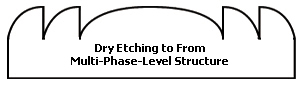

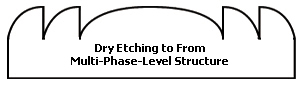

Using the HEBS-glass gray level mask fabrication and a following optical exposure, alignment errors are avoided, since the mask is written in a single step using different electron beam dosages to generate gray levels. This new approach also allows a very economical mask fabrication. Instead of fabricating of a set of five binary masks with all the involved resist processing and wet etching, only a single writing step without any resist processing is needed. This single mask then contains all the necessary information previously contained in a set of five binary chrome masks. Misalignment due to sequential printing of five binary masks in a set is completely avoided. After the HEBS gray level mask is fabricated a series of single exposures in a step-and-repeat system can generate hundreds of DOEs on the same wafer. This wafer can then then be processed with a single CAIBE step to transfer the DOE structure of a large number of different elements simultaneously into the substrate. Since the complete DOE structure is transferred into the substrate there is no need for a resist stripping step after the etching process. After dicing the wafer, hundreds of monolithic multilevel DOEs have been generated by a process which cut the involved processing steps by more than a factor of five. |

- High DOE efficiency because:

- Sharp zone boundries are realized using e-beam direct write on HEBS glass which has no graininess.

- Smooth Continuous blaze surfaces are realizable since there is no additional cost to increase the number of gray levels.

- One step fabrication of a true gray level mask.

- Reduced Cost of Mask

- One mask, one photolithographic step, no mask overlay errors.

- Cost saving from cutting DOE fabrication steps by more than a factor of 5, and faster turnaround.

Detailed Information of the HEBS-glass Blanks

|