|

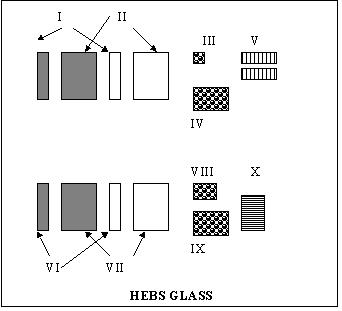

Test patterns Part VI to X which were written with E-beam write scheme No. 2 produces OD values of 0.284 to 2.006 in HEBS-glass I85 plate:

Part I: This part helps users to match photoresist heights with specific optical density values (OD, or D herein after) in the range of 0.115 to 1.153 in the mask to build a calibration curve "height of photoresist after development vs. OD of mask pattern." Part I exhibits 200 gray levels that are identified with labels, ranging from 00 to 199. Each gray level consists of one test patch, each test patch being 100µm x 100µm in size. The gray level i has an optical density value at 436nm wavelength according to the equation D = 0.115 + 0.005216i, where i = 0, 1, 2 . . . 199. Thus, by using the equation, the minimum and maximum OD value of 200 patches can be determined to be 0.115 and 1.153, respectively. Although there are only 200 OD levels in the calibration patches, mask patterns having 1000 gray levels can be written in a HEBS-Glass Plate reproducibly. Any arbitrary value of OD in the OD range of 0.115 to 1.153 can be produced in HEBS-Glass Plate I85 to a precision of +/- 0.001 between adjacent gray levels. There exists no universal calibration curve that is valid for all users. Height of photoresist after development may be a linear or a monotonic nonlinear function of transmittance of a mask pattern, or maybe a linear or a monotonic nonlinear function of OD of a mask pattern. The variable parameters governing the calibration curve include the variable parameters of photolithography tools such as exposure wavelength and intensity, and the variable parameters of photoresists and development including the type of photoresist and the as-coated thickness of photoresist. Nevertheless, when as coated photoresist thickness is very thin such as less than 1 micrometer, it is likely that the height of photoresist after development is a linear function of the transmittance (T here in after) of the mask pattern. Part II: Part II consists of tapered structures of variable heights for applications such as micro-prisms and micro-mirrors and other 3-dimensional structures, each facet may have a unique compound tilt. The first column (00) are tapered structures with a constant delta OD and the second column (01) are tapered structures with a constant delta T between adjacent gray levels. Each 100mm x 100mm prism is built with 50 gray levels. The formula for the OD values of the 50 graylevels in each of 20 prisms of column 00 is Odi = ODmin + [(ODmax - ODmin)/49]*i, where i = 0, 1, 2, 3, 4,…,49. The formula for the transmittance values of the 50 graylevels in each of 20 prisms of column 01 is Ti = Tmax-[(Tmax-Tmin)/49]*i, where i = 0, 1, 2, 3, 4…,49. The OD ranges and the corresponding transmittance ranges for the prisms in both column 00 and 01 are as follows:

Part III: Exemplary 4 x 5 subarrays selected from an array of microlenses having a variable lens parameter within the array. In this example, the lenslets within each subarray has a unique compound tilt. The facet centerline angle of the lenslet is the variable parameter and is a function of distance r from the optical center of the lens array. The range of facet centerline angles displayed is from 4.277 to 17.23 degrees. Each lenslet is 57mm x 57mm and is written with 20 gray levels. The lens sag determined by the OD range of the gray levels within a lenslet, increases with an increasing facet centerline angle. HEBS-glass enables users to create new as well as traditional designs of microlens arrays.

|

| Company | Technology | Products | Online Help | Contact |